The demand for semiconductor market continues to be hot, leading to the development of JiaDeng and JiaShanghai operation

The manufacturer of the crystal circle conveying solution announced that the merger will be collected in August, with the amount of NT$560 million, an increase of 10.5% from July and a decrease of 13.3% from the same period in 2024. The cumulative amount was about 4.486 billion yuan in the first eight months, a decrease of 0.54% compared with the same period in 2024. The company said that this season has entered the full-scale preparation stage, with the delivery of photocoat loaders and crystal round loaders expected, and all new products have also entered the verification key stage, and it is expected that the mainland will continue to invest.

As the investment market is stable in the second half of the year, Jiadeng has gradually arrived at its peak shipping period, benefiting from the full capacity of advanced process and large customers, and the shipment of ultraviolet EUV of the optical shield carrier has been stable and increased throughout the year, meeting customers' new process needs.

In addition, the next generation of high-NA EUV Pod adheres to higher micro-disease prevention and control requirements, and Jiaden has been the only certification of ASML in the world. In terms of advanced process crystal loaders, shipments in various regions have gradually returned to stability in the second half of the year. Jiadeng fully cooperates with customers to optimize process and upgrade loaders, and hopes to further expand the market.

In addition, the semi-conductor equipment cleaning factory merchant under Jiadeng Group also announced that it would receive a purchase in August, with a total of NT$112 million, a growth of 6.4% compared with the same period in 2024. The profits of the industry's revenue remain stable. Benefiting from the promotion of demand for semiconductor 2-nanometer production and EUV mask charging, Nanke's short-term production capacity has been fully expanded, and it is preferred to support the delivery of EUV mask charging-related machines, and reserves the production capacity to provide yellow light and advanced packaging application production. The company is still cautious about its annual operation prospects.

Homework focuses on the semiconductor microfilm production process to transmit automatic equipment. The company has been deeply engaged in the refill technology of mask cleaning, exchange, storage and inspection for many years. The R&D team has a strong patent plan, and its quality is stable and high added value has been certified and adopted by many international factories. It has entered the supply chain of global crystal manufacturing leading manufacturers. Jiasheng Technology said that it will continue to invest in overseas market layout and cultivation in 2025, and will recently win customers' youth in EUV mask transmission and mask testing equipment in the United States and Japan, which is expected to be an important key to the company's entry into the Japanese semiconductor supply chain.

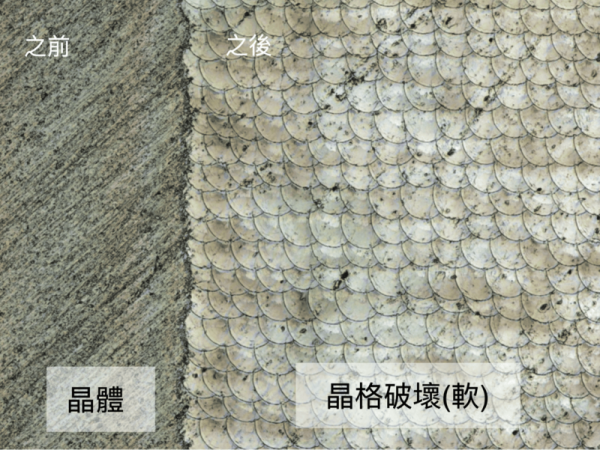

Business and R&D strategies, Jiashu focuses on developing new applications of advanced process equipment, expands the application of mask detection and exchange of machines to Huangguang process, and extends mask cleaning and testing technology to advanced packaging process applications. Moreover, due to the development of semiconductor industry and the continuous development of the environment, the family and customers cooperate to innovate and improve gas-enhancing technology. This solution will help optimize gas-enabled gas usage and apply traffic automation measurement technology to EUV and high-level mask charging processes, and is expected to be introduced into customer production lines in 2026.